- How to upgrade Hi5a controller version

- Separate use of TP520, TP530 SW

- Understanding robot payload

- Notice on prohibition of mixing reducer grease (VIGO + EUREKA)

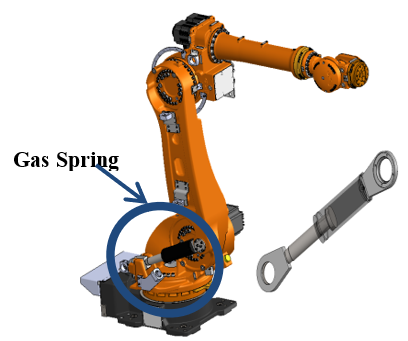

- Gas spring management (monitoring)

- Gas spring management (pressure inspection, injection)

- Gas spring maintenance (inspection)

- How to check HH7 robot origin

- Gas spring management method, inspection and replacement cycle

- Notice of discontinuation of Hi3 robot parts

How to upgrade Hi5a controller version

1. Prior knowledge

- You must prepare a USB memory containing the files required for version upgrade.

- Deployment files must be named in a defined format.

ex) Hi5aV402600.zip

controller model(Hi5a) + V + major version(40) + minor version(26) + build revision(00)

- All Hi5a controllers have a major version of "40" no see.

- The minor version (26) is the actual significant version number.

- The build revision is "00" for all official versions and all other versions are trial versions.

- The Hi5a version is provided in ZIP format and is unpacked and installed by an automatic installer. (There is no need to intentionally unzip it.)

1.1. Precautions when downloading version

- MV40 for TP530 users. If you download the version from 24 or higher to MV40.23 or lower, you cannot change the main version.

- TP520/511 users are irrelevant.

- After downloading the main version using TP520, you must reconnect and use TP530. At this time, when changing the version, only TP is performed.

2. Task sequence

2.1. Create a version upgrade folder with the name “Hi5a_rel” at the top path of the USB memory (based on TP511 \USB).

\USB\Hi5a_rel

2.2. Copy the Hi5a controller S/W distribution file to the USB version upgrade folder.

release file : for case : Hi5aV402600.zip

EX) \USB\Hi5a_rel\Hi5aV402600.zip

2.3. Connect the USB where the distribution file is copied to the T/P.

2.4. Confirm that the T/P screen is switched as shown below.

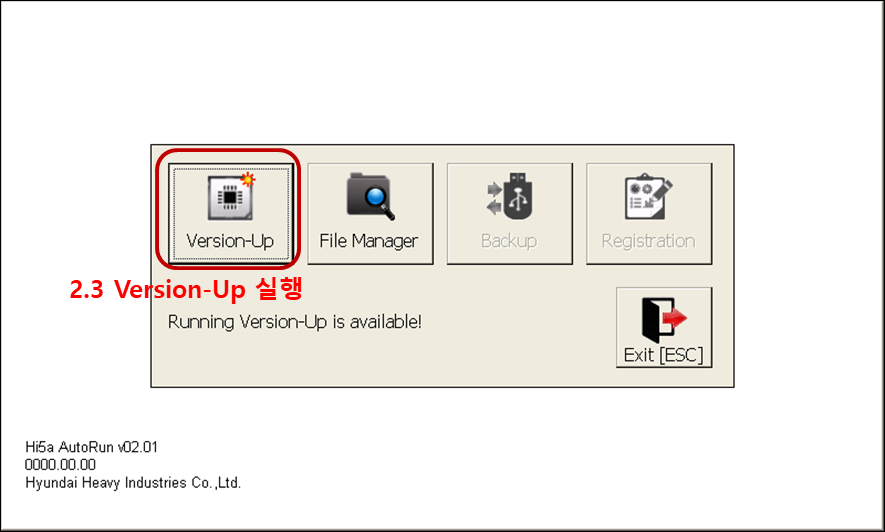

2.5. Press the Version-Up button.

caution

- Work with motor_off

- Working in manual mode

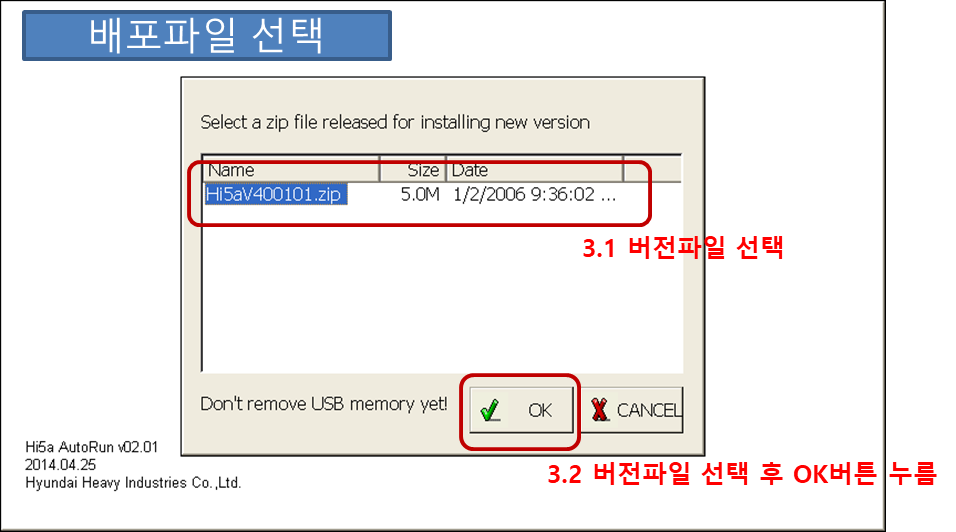

2.6. After confirming that the screen changes as shown below, select the distribution file copied to the USB.

2.7. Confirm that the distribution file is selected and press the “OK” button.

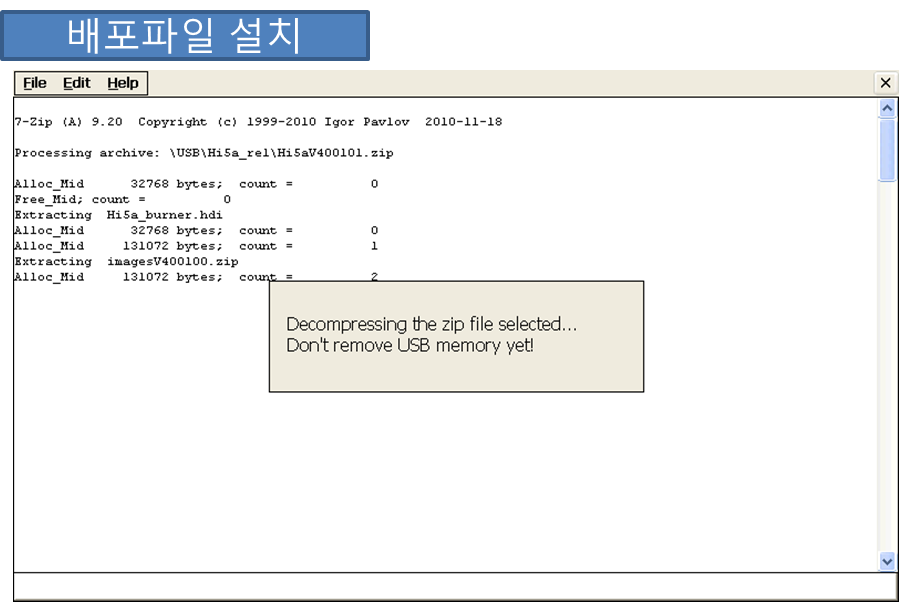

2.8. The process of installing the distribution file on the T/P proceeds automatically. (Do not remove the attached USB while the above process is in progress)

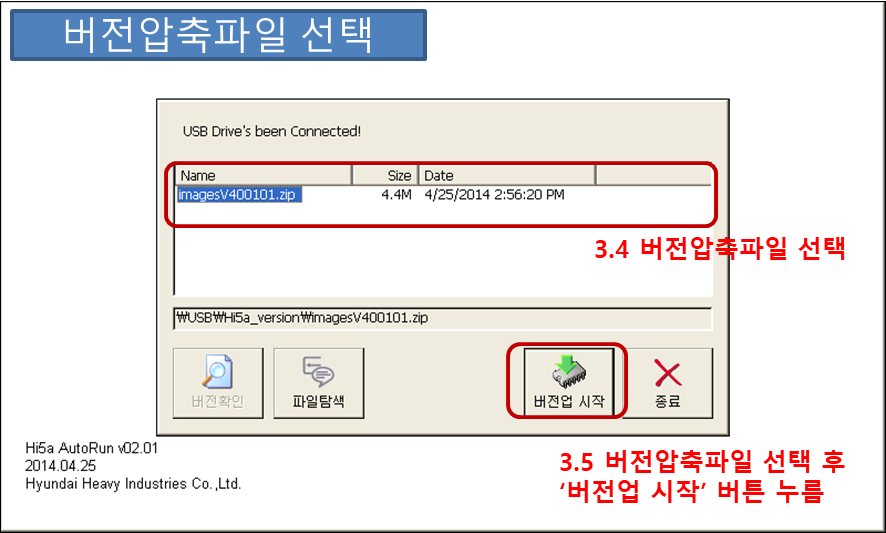

2.9. Select the version compressed file that integrates the version upgrade files for each device.

Select the 2.10 version compressed file and press the ‘Start version upgrade’ button.

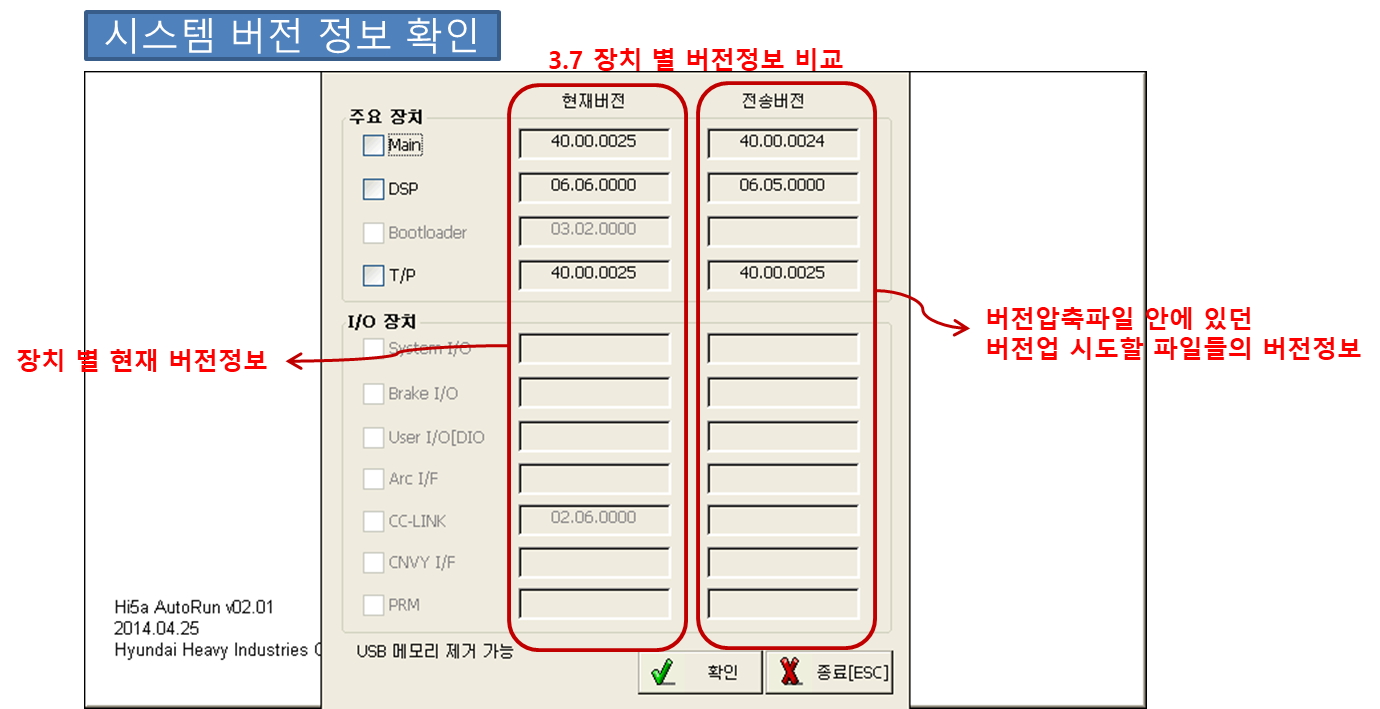

2.11 Automatically switches to a screen where you can check system information.

2.12 Compare version information for each device.

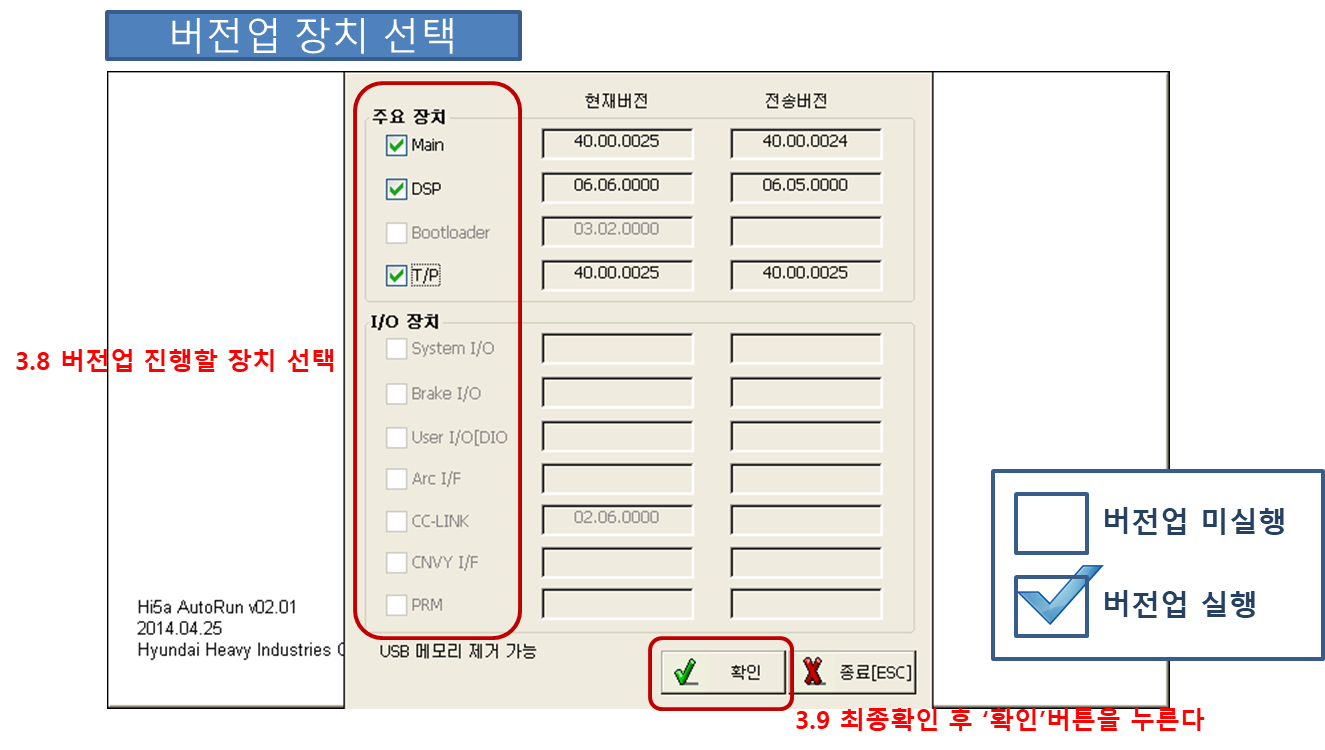

2.13 Click the checkbox of the device for which you want to upgrade to version 2.13 and change it to the checked state.

(You can upgrade only the parts you want.)

2.14 After final confirmation, press the ‘Confirm’ button.

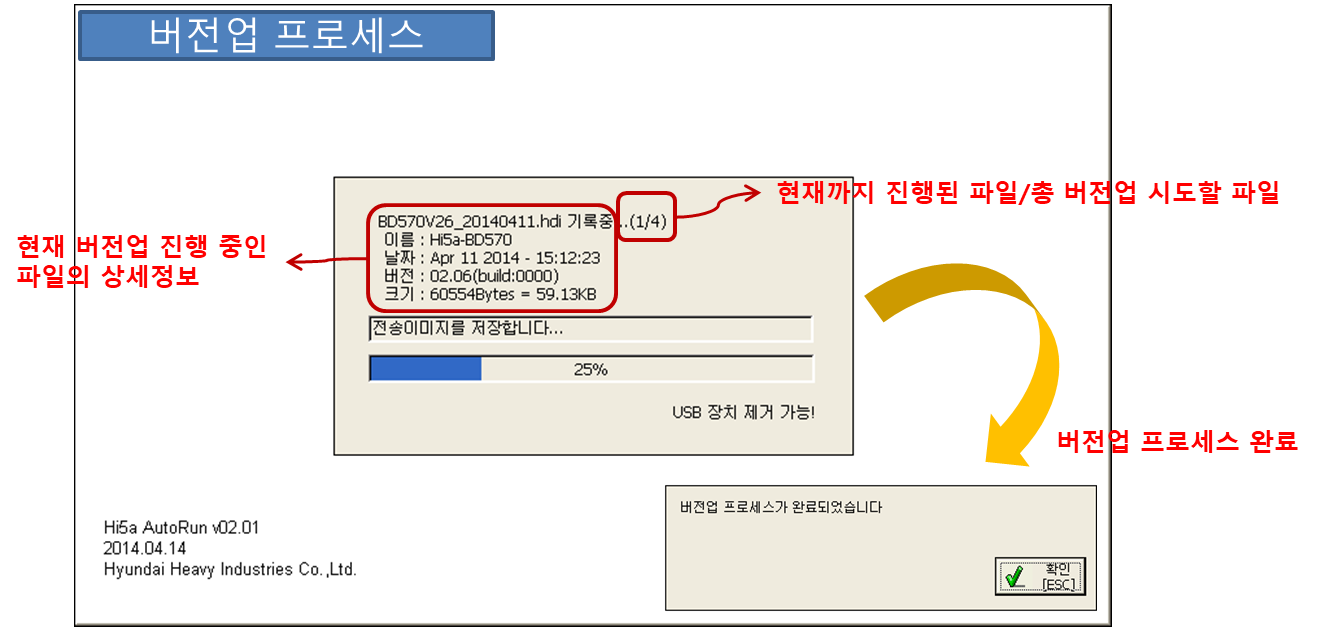

2.15. The version upgrade for the selected device (single or multiple devices) is automatically performed.

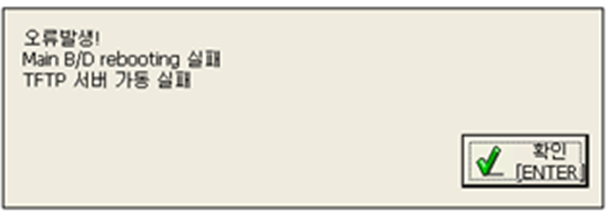

3. An error occurred during installation

3.1. Distribution file installation failed

3.1.1. Cause

- If the USB is arbitrarily removed from the T/P during installation of distribution files

- When the distribution file itself is invalid (file is broken)

3.1.2. Solution

- Reinstall the USB and try upgrading again.

- If the file is corrupted, it must be replaced with a normal distribution file. (Please re-request the distribution file.)

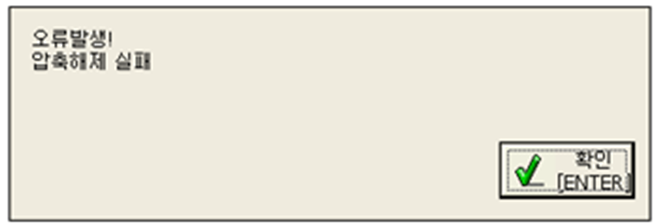

3.2. Decompression failed

3.2.1. Cause

- Occurs when the temporary storage space inside the T/P is insufficient.

- Occurs when the distribution file or version compressed file is broken.

3.2.2. Solution

- If the cause is insufficient temporary storage space, restart the T/P device.

- If the file is damaged, replace it with a normal distribution file and apply.

3.3. Communication error

3.3.1. Cause

- Poor Ethernet cable connection between main board and T/P

- Main S/W is unable to communicate

3.3.2. Solution

- Check the Ethernet cable wiring condition and retry.

- Restart the Hi5a controller. (OFF -> ON)

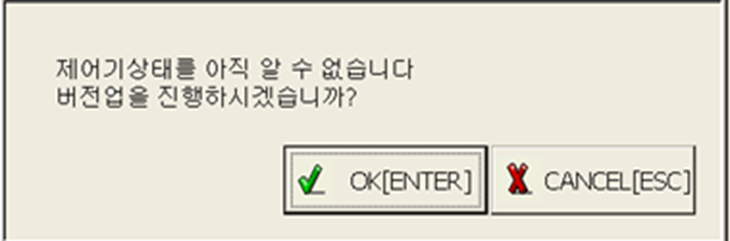

3.4. Controller status not received

3.4.1. Cause

- Communication error

- Main S/W malfunction

3.4.2. Solution

- In case of communication error, check error measures.

- In case of main S/W malfunction, ignore it and proceed. (Press OK button) In case of main S/W malfunction, 7-segment of Main B/D: E52, dbg.

Separate use of TP520, TP530 SW

Problem

- Since the S/W of TP520 and TP530 are different, problems arise when installing unsuitable S/W.

Precautions

- TP520 and TP530 cases are the same.

- JOB program and UI Compatible without change.

- Differences in Win OS There may be differences in S/W. (see next)

- TP530 S/W cannot be installed on TP520 H/W. (Same for vice versa)

- EX) MV40.21 (for TP520) ≠ MV40.21 (for TP530)

- Installing another OS may occasionally cause TP system errors.

Differences between TP520 and TP530

division | TP520 | TP530 |

RAM | DDR2 256Mbyte (400MHz) | DDR3 1Gbyte (933MHz) |

Memory | NAND Flash 1GByte | eMMC Flash 8GByte |

OS | Window CE 6.0 (TP511 has the same S/W as TP520) | Window Embedded Compact |

※ The appearance of TP520 and TP530 is the same.

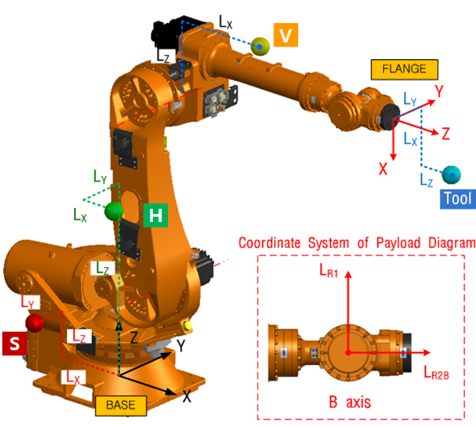

Understanding robot payload

Understanding allowable torque and moment of inertia

- The payload of the robot (Payload: model below - 165Kg) is sufficient for the robot to carry and work. It refers to the weight.

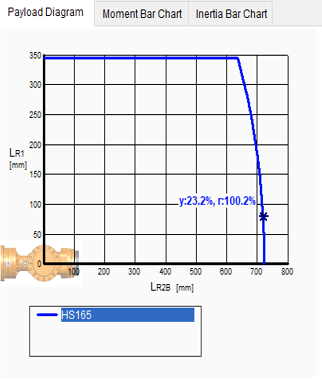

- Even if the payload is 165Kg, the farther the center of gravity is from the reference point, the more torque there is. As it gets bigger, the allowable payload becomes smaller . (See picture below)

- Based on the center of gravity Even if the torque value is the same, the moment of inertia varies depending on the speed. It gets bigger.

- In other words, even if the tool or workpiece is light if the center of gravity is far from the reference point, The allowable payload decreases drastically.

- If the moment of inertia or torque exceeds, the distance from the possible reference point is determined. It is better to reduce it.

- The allowable payload of the robot is proportional to the tool weight and the square of the distance. It is inversely proportional.

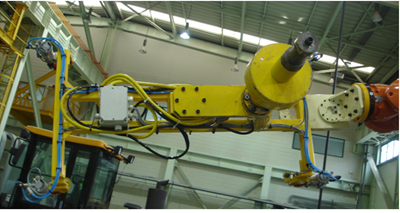

Excess Use Cases

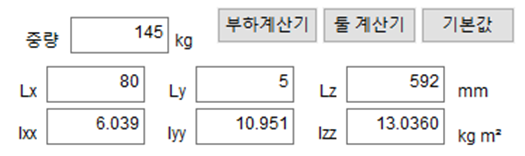

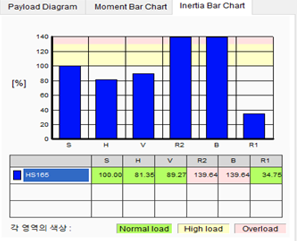

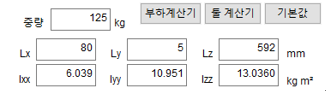

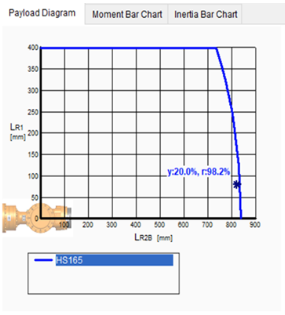

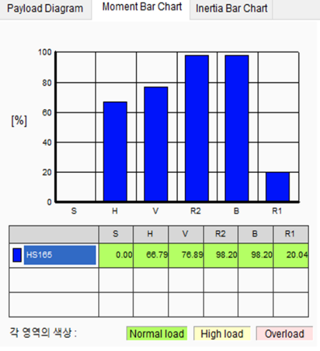

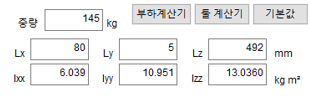

Applicable robot: HS165 (carrying weight 165Kg), tool (145Kg)

It seems that there will be no problem by installing a tool that is less than the payload, but the tool The distance between the center and the reference point appears far.

(Robot: HS165, tool weight: 145Kg)

Find the distance and inertia of the tool's center of mass.

- Use robot load estimation software

- Use of 3D modeling data from tools

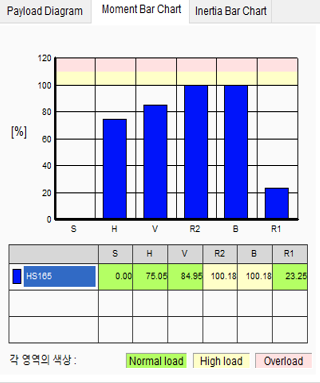

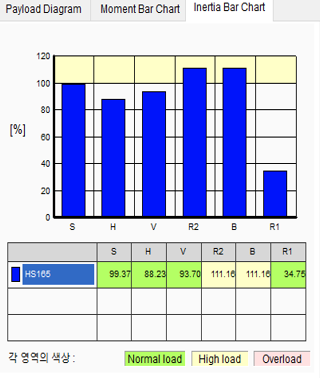

The result of applying the load calculation is as follows.

- Weight: Outside the range of use.

- Torque: 4,5 axes not available

- Inertia: Not available for 4th and 5th axes

How to improve when overload

- If the load is exceeded, reduce the tool weight or **reduce the load to the center of gravity of the tool. There is a way** to reduce the distance.

- A method of reducing the distance is more effective. There are two ways as follows: When improving by method , if only the weight is reduced, the excess inertia will not be improved. No.

- Load calculation uses our load analysis program HRLoad. (HRLoad download)

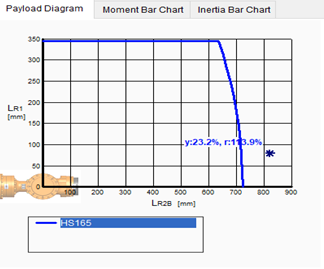

When reducing weight

- Tool weight reduced by 20kg from 145kg to 125kg

- HRLoad analysis results

- Weight is within tolerance (on borderline)

- Torque value within tolerance

- Exceeding the inertia tolerance (when used, the lifespan of the relevant axis is shortened)

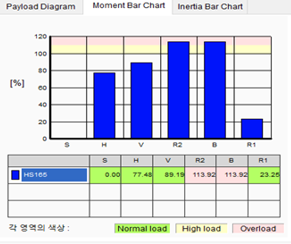

When shortening the length

- The tool weight remains the same, but the z-axis distance to the tool center is shortened by 100 mm.

- HRLoad analysis results

- Weight is within tolerance (on borderline)

- Torque value within tolerance

- Can be used with inertia tolerance high load (although the lifespan of the relevant axis will be shortened) 1)Better than inside.)

Notice on prohibition of mixing reducer grease (VIGO + EUREKA)

EUREKA 114 was developed to solve the initial noise problem of VIGO RE 0 . , VIGO This product has greatly improved initial test operation noise compared to grease. However, please be aware that mixing the above greases together in the same reducer may cause some noise.

1. Problem

- VIGO + EUREKA Noise occurs when mixed oil

- Noise persists when the ratio of VIGO or EUREKA is more than 20%

2. History

The grease for the reducer applied to our robots is as follows.

- VIGO RE 0: Period of use 2014 ~ 2020.9 (based on HS165, HS220)

- EUREKA 114: Period of use 2020.9 ~ (based on HS220)

3. There is no major problem if you inject it after removing the existing grease.

If you are working with mixed grease, please replace it using the method below.

- Residual amount suggested by manufacturer: 10% (Noise usually disappears when less than 20%)

- In order to maintain the remaining oil amount below 10% during actual grease replacement work, the push method must be performed more than 3 times.

Reference 1. grease can

VIGO RE0

EUREKA 114

Reference 2. grease filler sticker

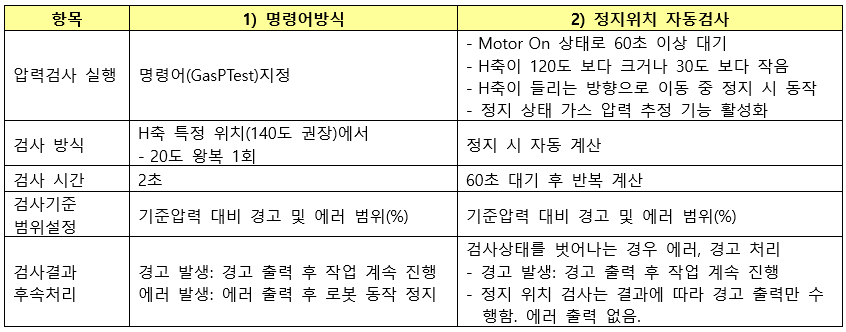

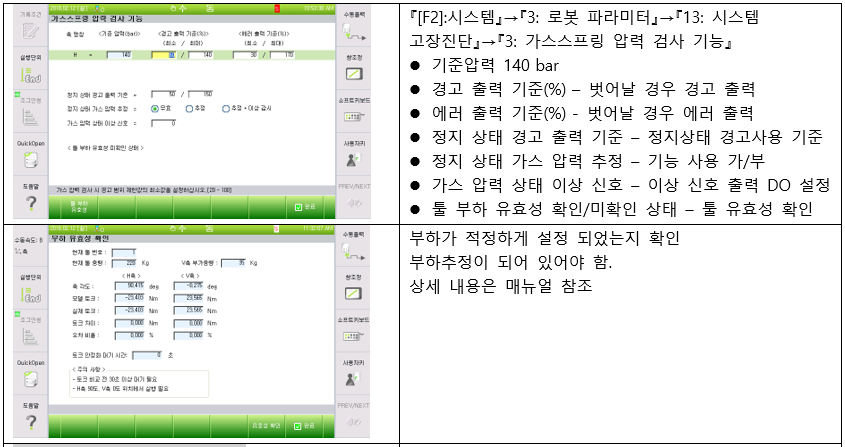

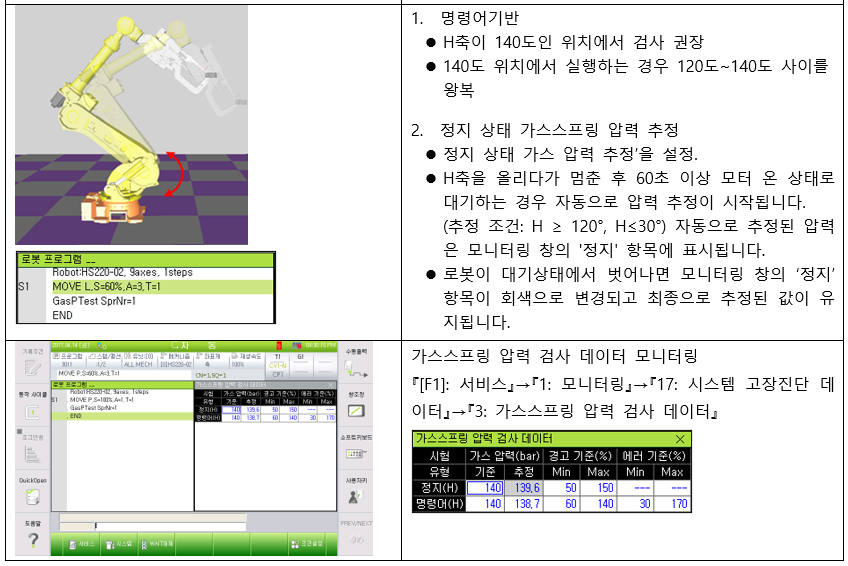

Gas spring management (monitoring)

Gas spring monitoring

Hi5a controller provides the function to monitor the pressure of the gas spring to manage the gas spring type balance spring.

The prerequisites for using this feature are as follows:

- Function provided only in controller main software MV40.17-00 or higher

- The actual pressure of the gas spring must be accurate. (140bar) – monitoring for subsequent changes

- Robot load estimation must be performed accurately.

See manual for details

Function comparison

Pressure estimated at rest is less accurate than pressure estimated using the command method. If an abnormal pressure is detected in a stopped state, re-estimate the pressure using the command method or measure the actual pressure using a pressure gauge. If the estimated pressure at rest is still significantly different from the estimated pressure by command method, set the 'Estimation gas pressure at rest' setting to 'Estimate' or 'Invalid'.

How to use

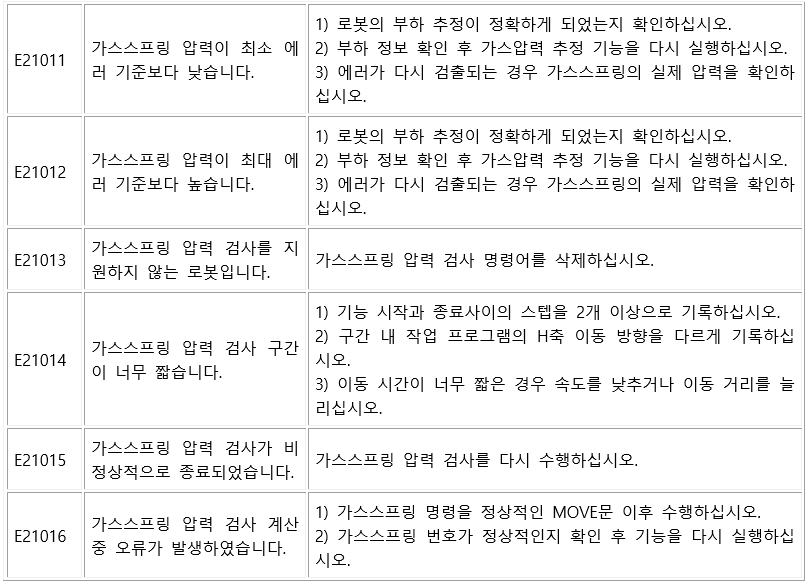

Error details

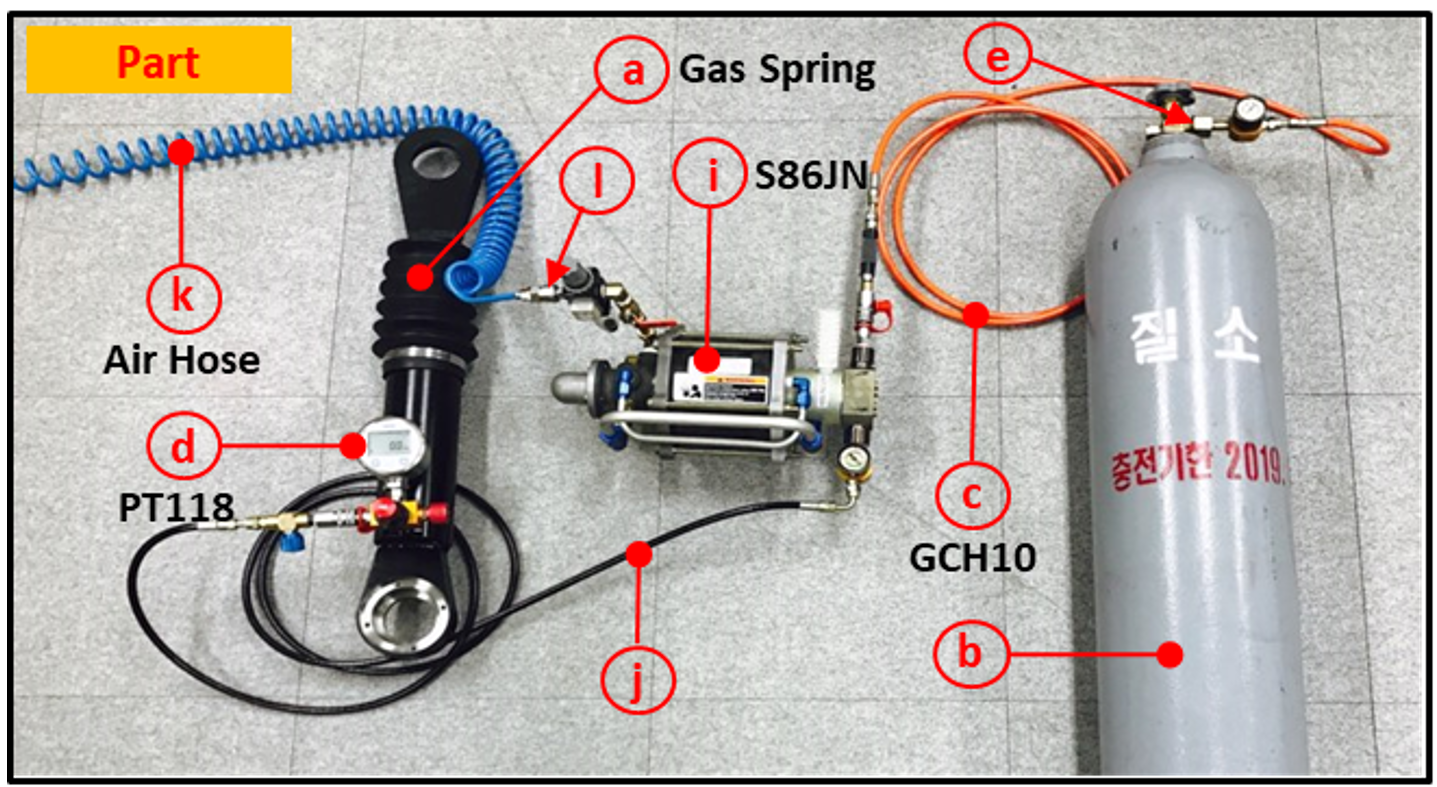

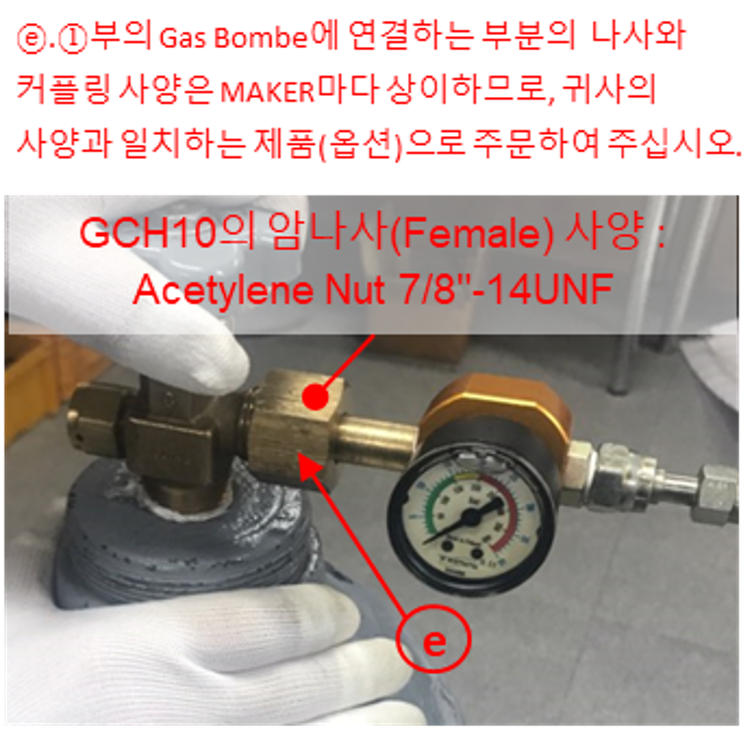

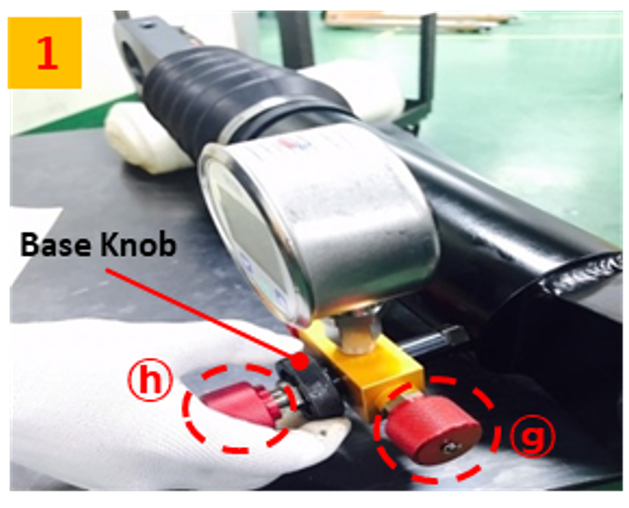

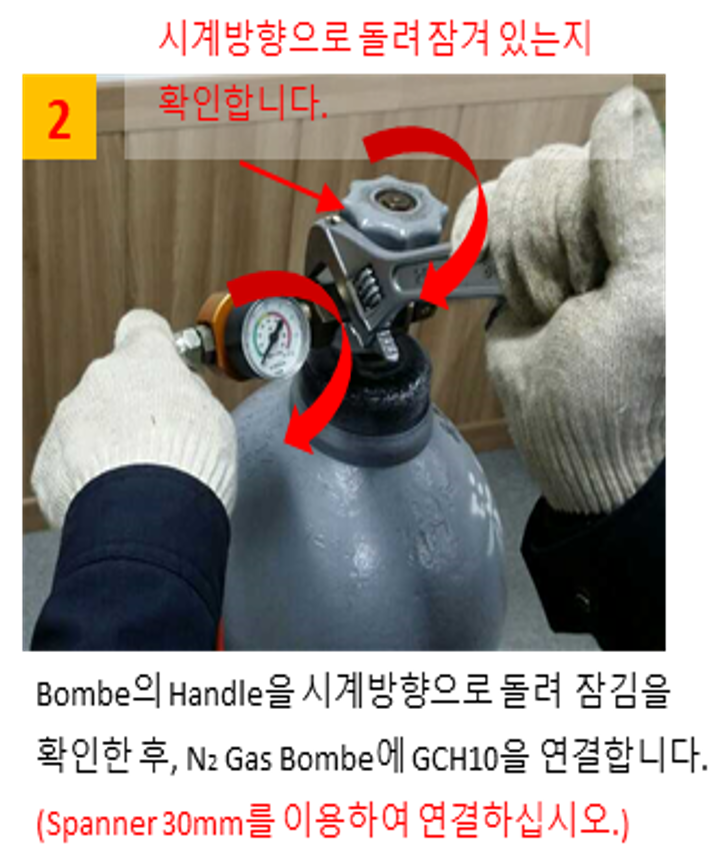

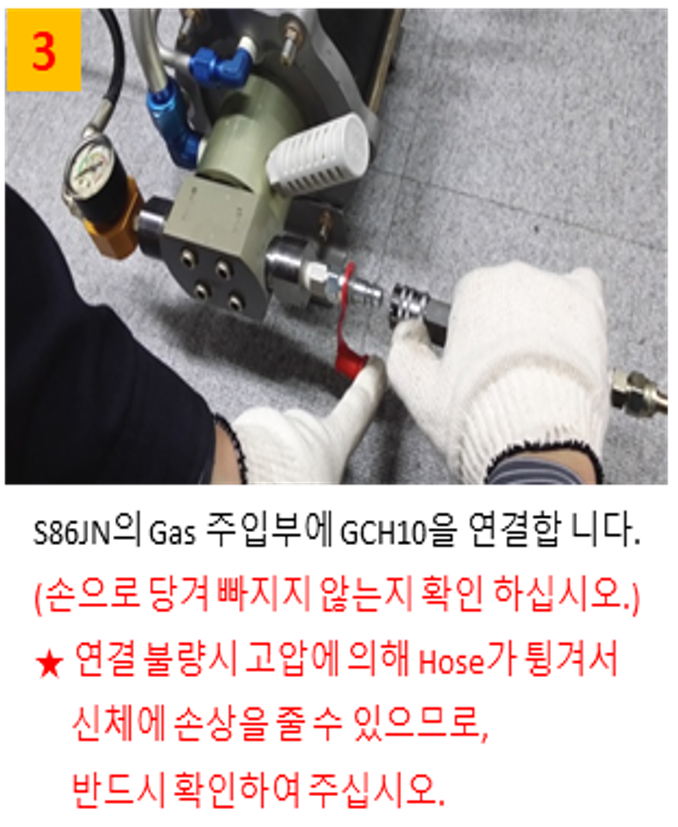

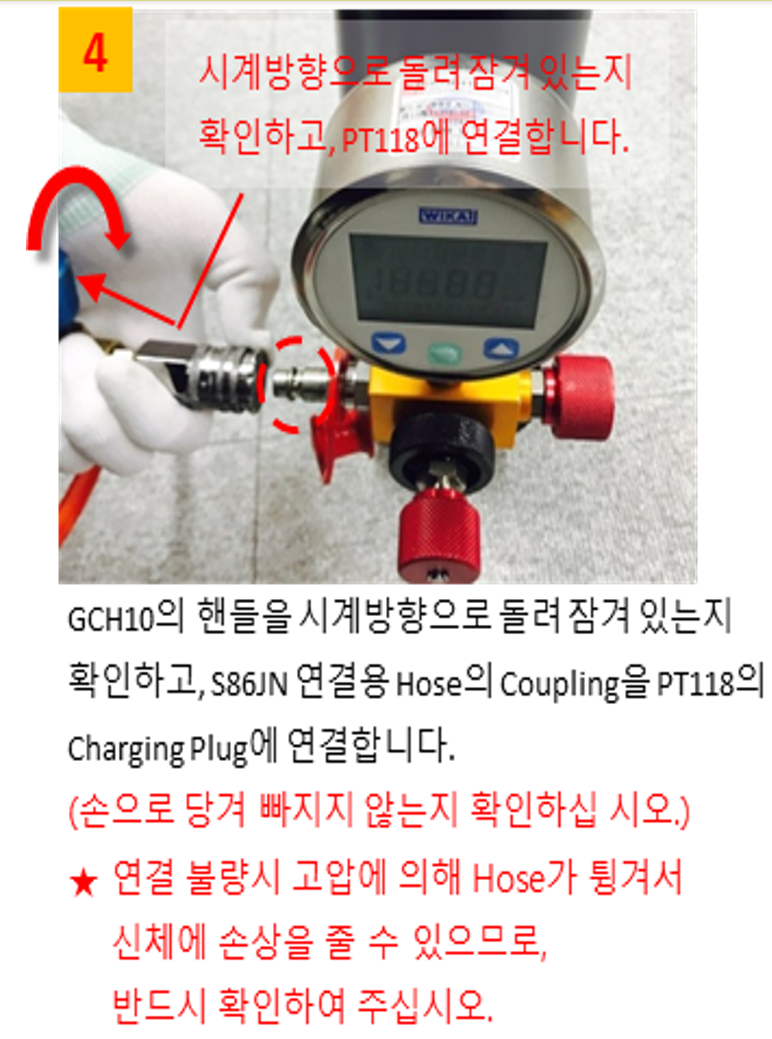

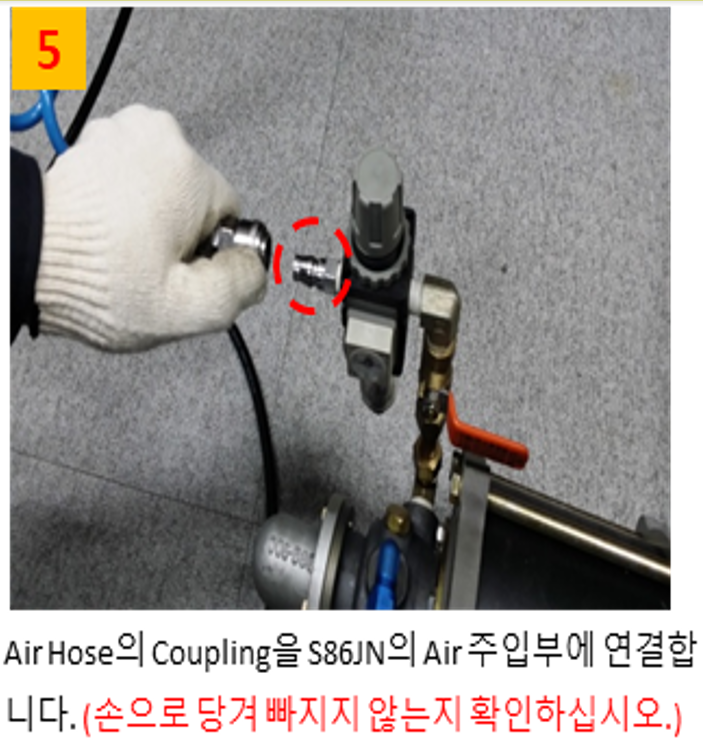

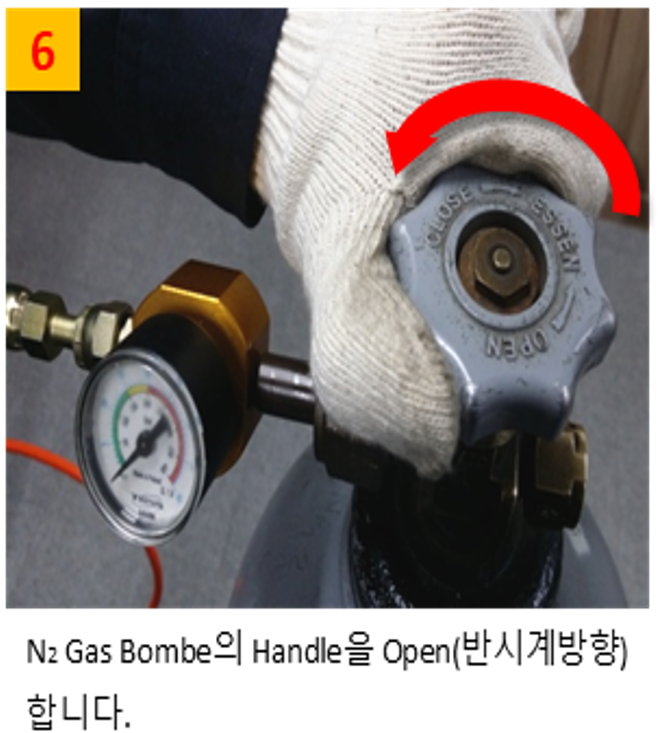

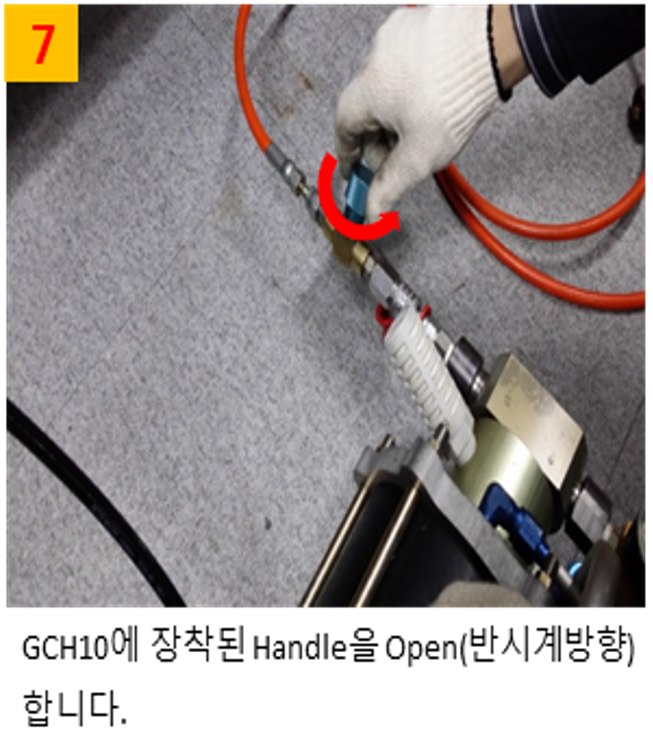

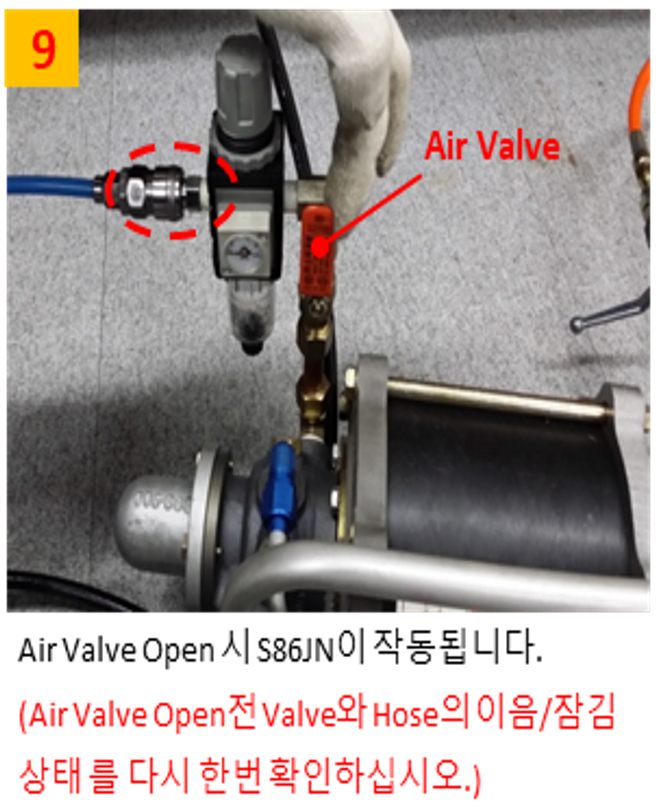

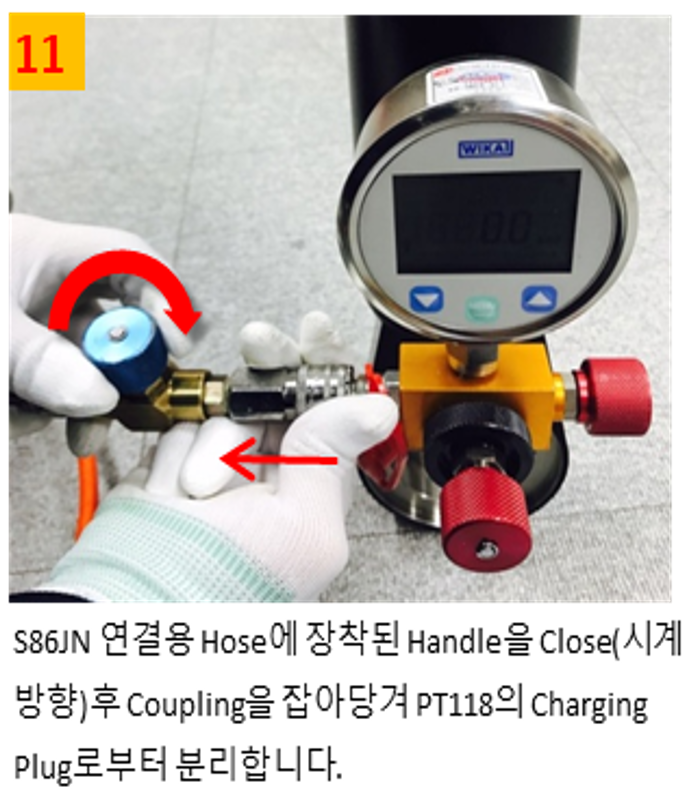

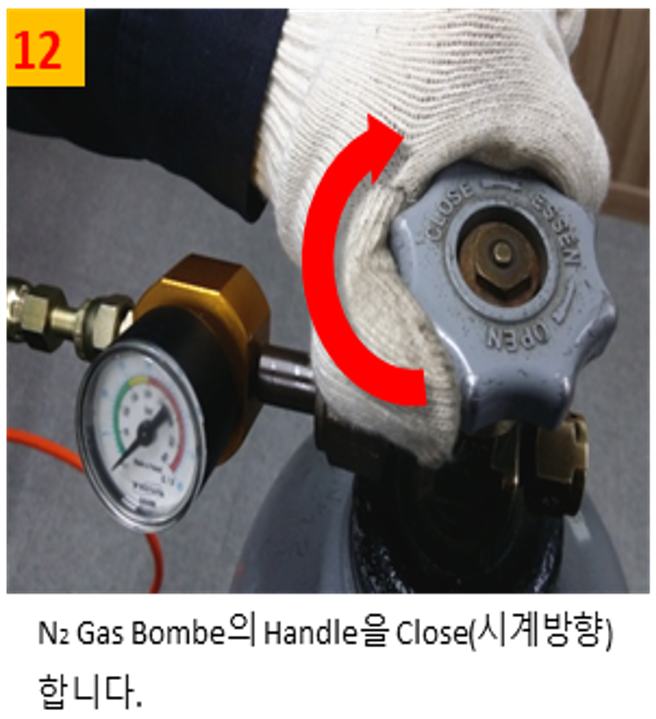

Gas spring management (pressure inspection, injection)

Gas pressure testing and injection

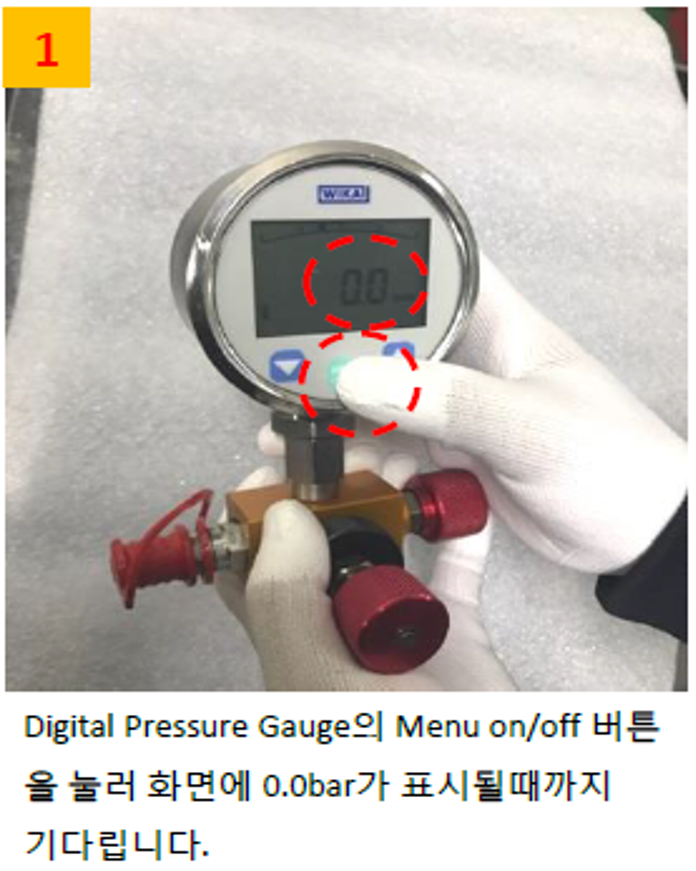

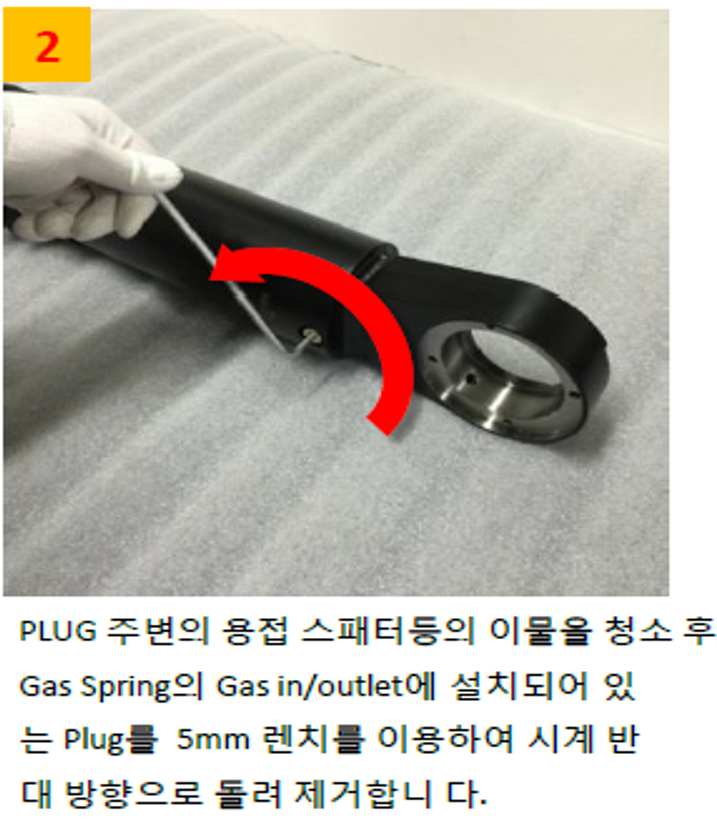

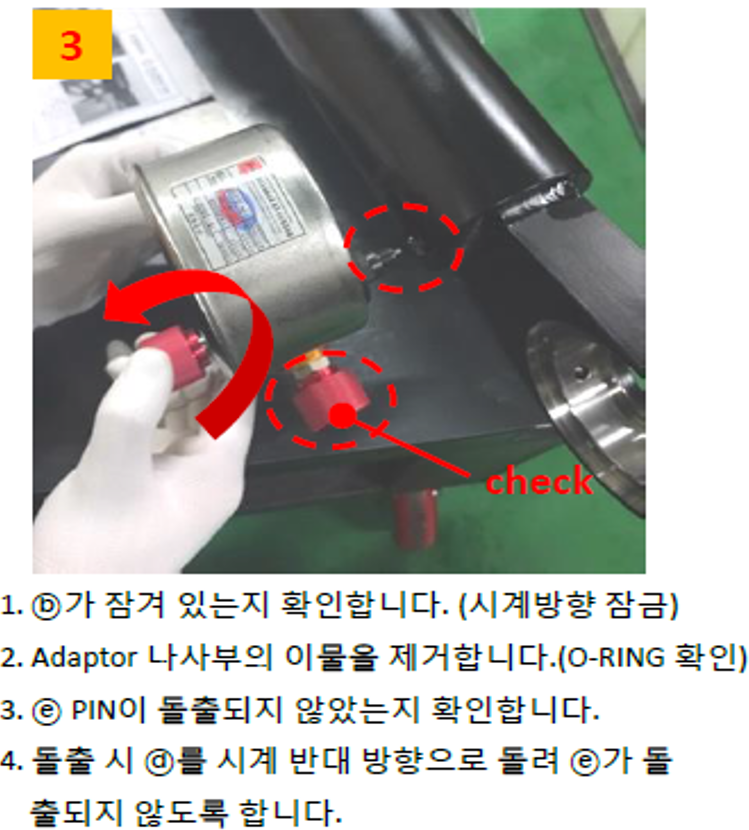

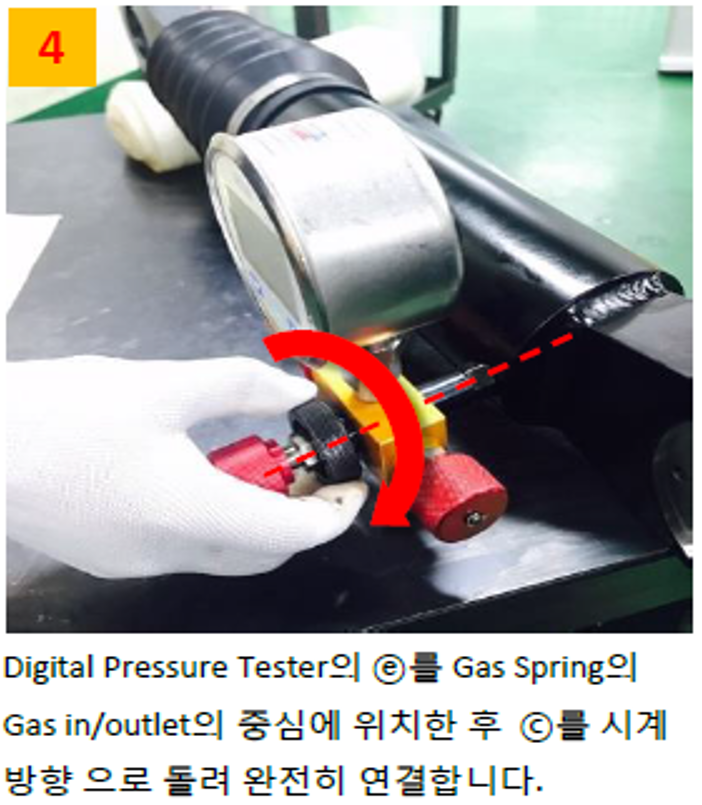

Pressure check

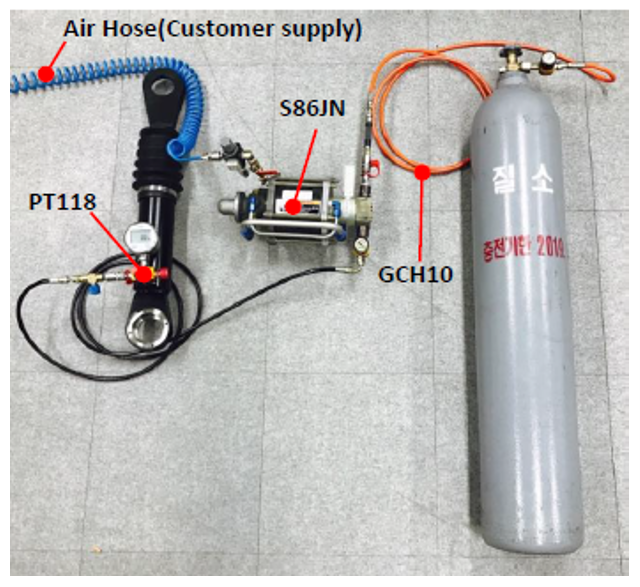

가스스프링 충진기 SET

가스스프링 충진기 SET

(디지탈 압력 측정기)

(디지탈 압력 측정기)

(압력 주입 부스터)

(압력 주입 부스터)

Pressure check

gas injection

- Since nitrogen gas filling is high pressure, please follow the safety regulations of your country.

- Nitrogen gas filling and inspection must be performed by trained personnel and in accordance with the manual.

- Please fill only nitrogen gas. (Never fill gases other than nitrogen gas or liquid nitrogen.)

- Be sure to wear safety glasses when working.

- Never look directly into the gas inlet or pressure gauge.

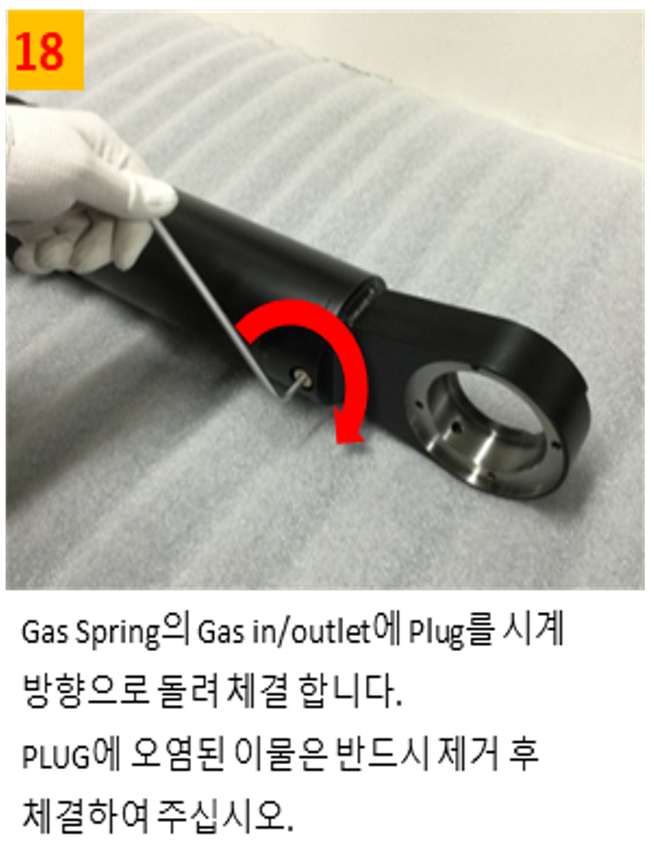

- If damage occurs, such as when assembling a gas spring with a different stroke, completely remove the gas and then separate it.

- For safety considerations and to preserve product performance, disassembly and assembly of gas spring internal parts can only be done using designated standard work tools and equipment with appropriate training and understanding of the product. For inquiries regarding this, please contact us. Please contact us.

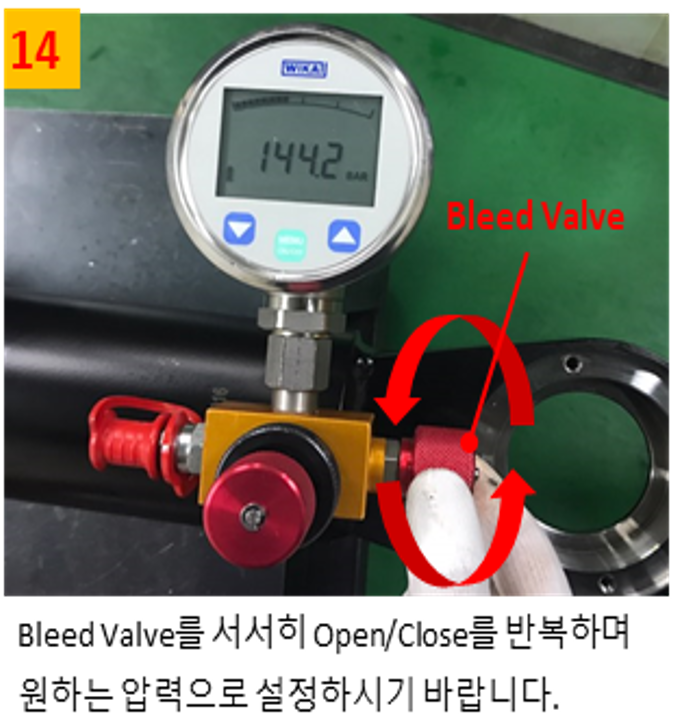

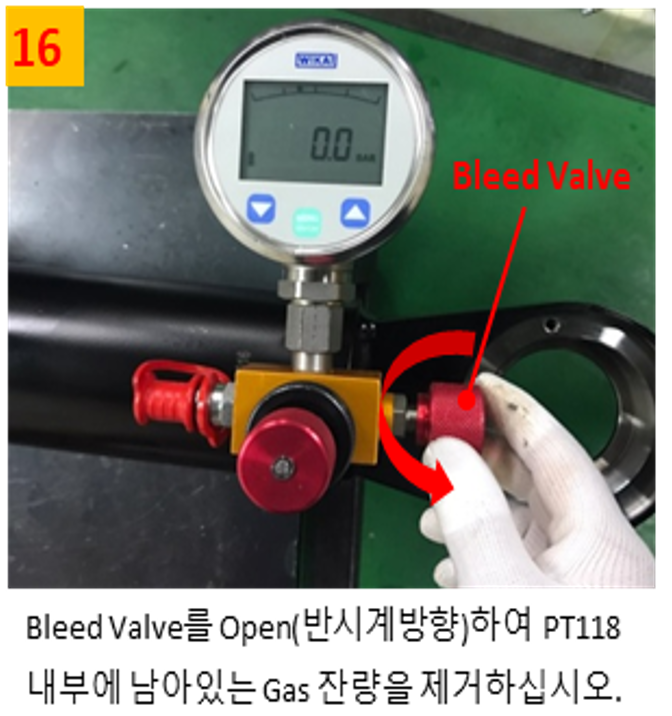

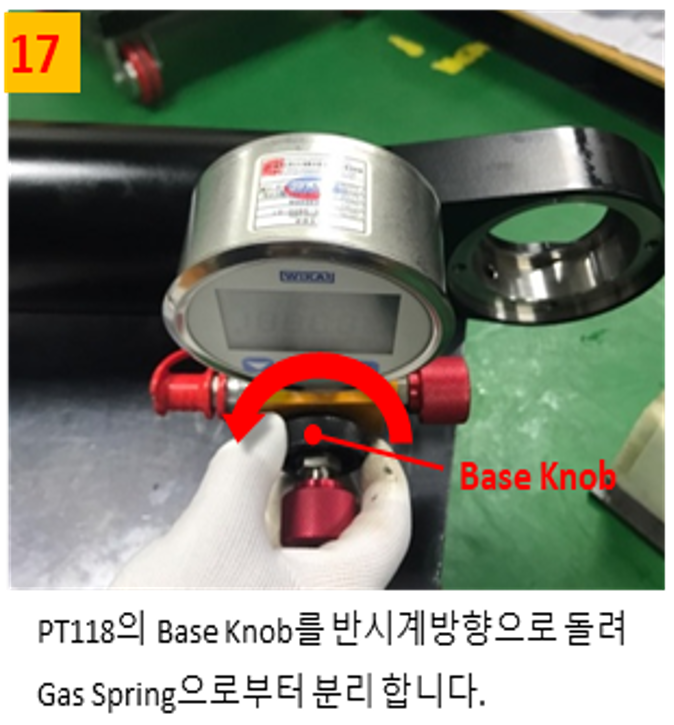

- When measuring gas pressure, please follow the manual as incorrect operation/mistakes of the measuring device can cause a decrease in gas pressure.

- Gas replenishment and filling must be performed with the gas spring assembled on the robot.

- Set the robot's H-axis (2 axes) posture to the origin of 90° and turn off the power to the controller.

Gas spring maintenance (inspection)

Gas springs have the advantage of being lighter and requiring less replacement time than coil springs, but as they are devices that use high-pressure gas, natural leaks occur. Periodic inspection by the user is required to manage this.

| Application Model | HS180/220, HH300,HS200L |

|---|---|

| Replacement M/H | 0.5 hours (depending on environment) |

| integrity | Periodic inspection. Twice a year (refer to manual) |

- Problem that occurs when gas spring pressure drops: H-axis overload error occurs (robot stops)

- Depends on the level of leakage. Depending on the load on the H axis, it may not occur even if the entire amount of leakage occurs.

- Overcurrent warning occurs (H-axis warning needs to be checked)

How to check pressure

Apply pressure automatic detection function (Hi5a version MV40.17.00 or higher)

- Warning occurs below 60 bar

- Error occurs below 30 bar (robot stops)

- Warning level can be manually set in T/P (details announced later)

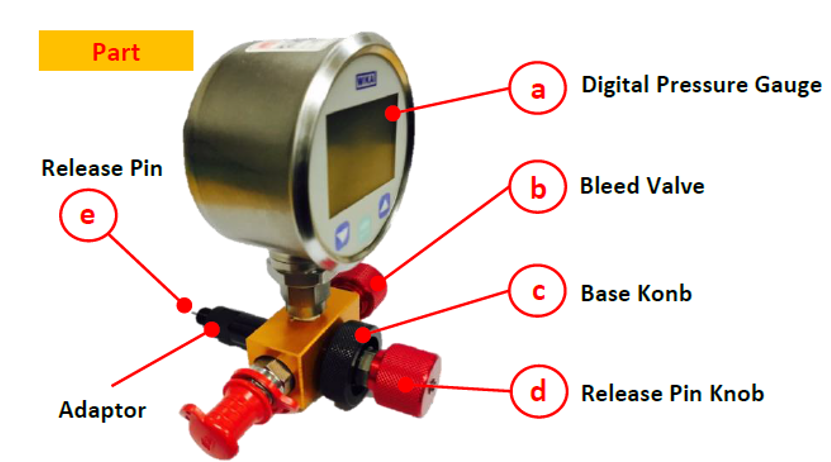

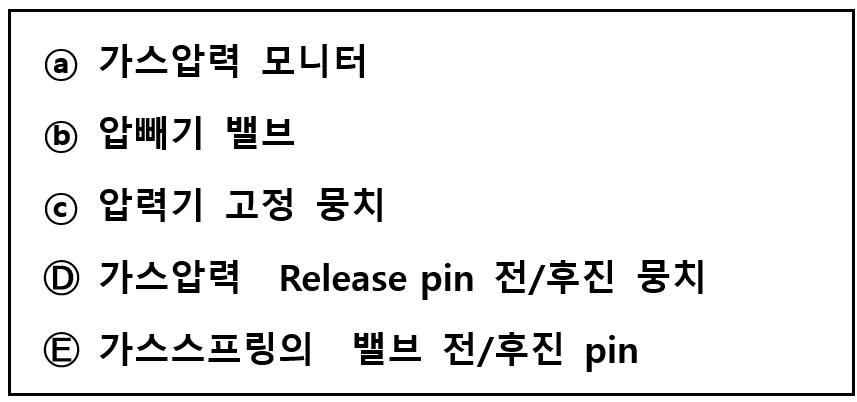

Manual measurement using a pressure gauge (general pressure gauge: digital (PT118) recommended)

How to respond when pressure drops

| pressure(bar) | Action take | meaning | note |

|---|---|---|---|

| 140~100 | maintain | There is no or minimal leakage. | |

| 100 or less | gas filling | Pressure decrease due to natural leakage | Use after filling |

| 100 or less | substitute | Rapid deterioration due to seal damage | First filling test required |

- Problems when using gas springs while neglecting natural pressure drop

- The friction angle between the cartridge and the tube increases, causing damage to the seal.

- Early damage to gas springs occurs

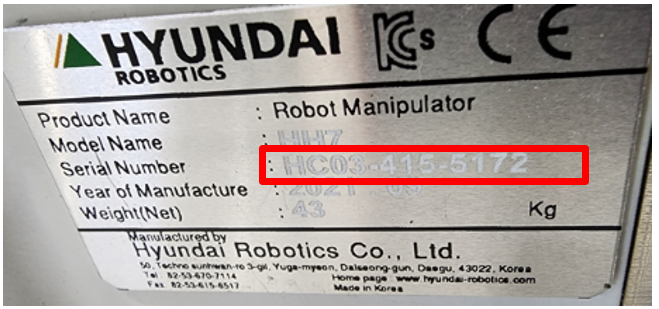

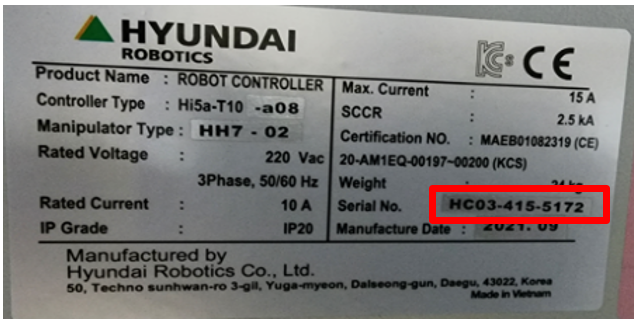

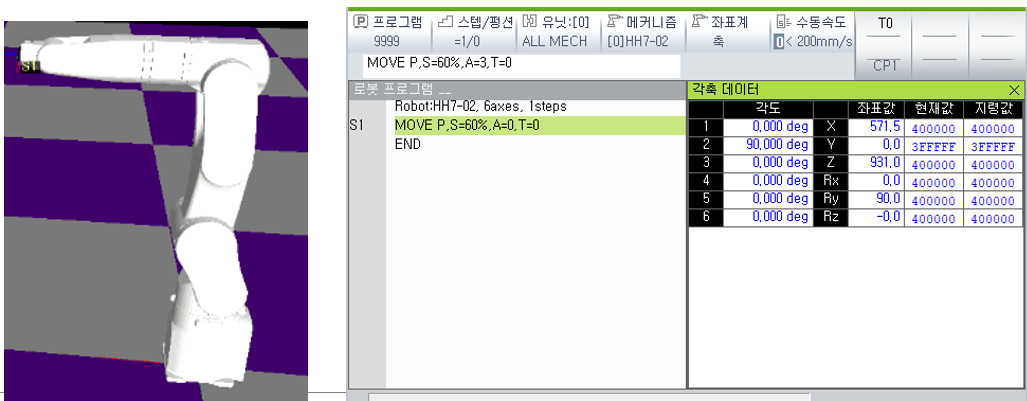

How to check HH7 robot origin

Check whether the robot body and the controller number are the sam

If there are multiple robots, be careful of mixing the main body and controller!

Select robot program (JOB file: No. 9999) and move

- Select program (press Shift key + Program-Step key simultaneously), enter 9999 and press ENTER

- Select step number (Press Program-Step key / 1 input ENTER)

- Robot operation: Motor ON - Deadman switch ON - Step forward (FDW) and move to step 1

- After moving, the data should be the left posture below and each axis data on the right.

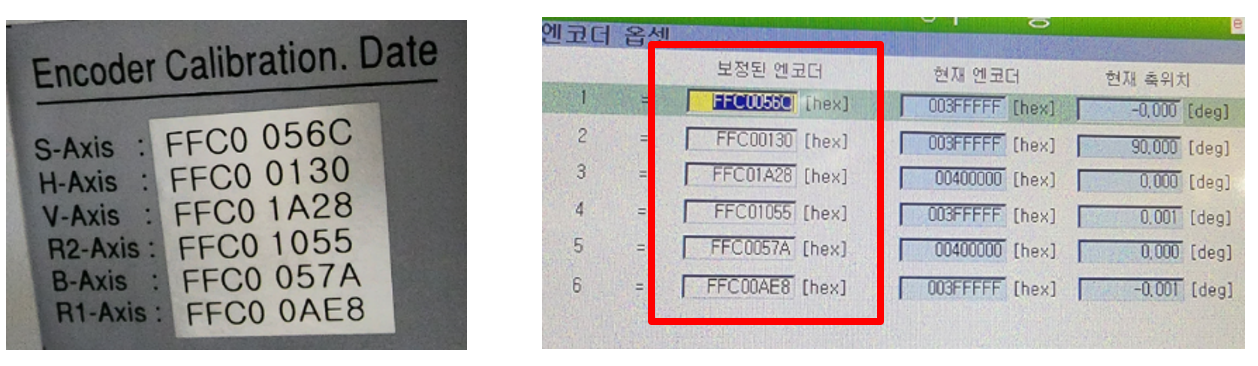

The encoder recorded value attached to the control panel and the left corrected encoder value of the TP encoder offset must be the same

(System – Robot Parameters – Encoder Options Screen)

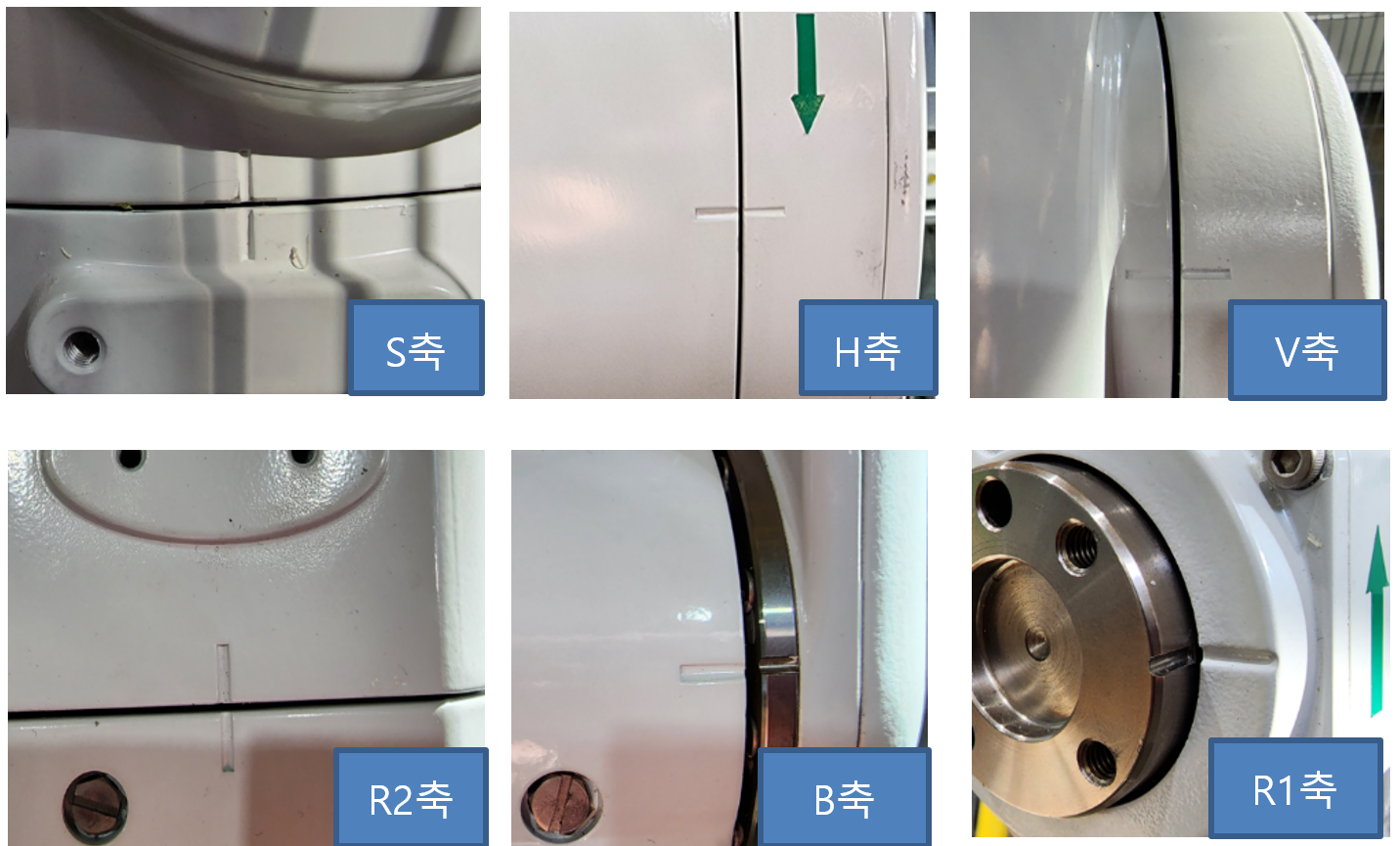

Check whether the scale of each axis of the robot body matches

Gas spring management method, inspection and replacement cycle

Please refer to the notice regarding maintenance precautions for the gas spring applied to the models supplied by our company.

target model

- HS220 series : HS220, HS180, HS160L, HS210E

- HH300 series : HH300, HS200L, HS260

Management method

Gas springs were adopted because they have the advantage of being lighter and easier to replace than coil springs, but as they are devices that use high-pressure gas, natural leaks may occur, so periodic inspection and replacement by the user is required. (Reference: Main unit manual 4-2)

Inspection is performed every 6 months, and gas charging or replacement is required if the pressure drops. (Reference for details: Chapter 9 of the main unit manual).

If leakage is left unattended, it may cause damage to the gas spring and drive system (motor/reducer). (Caution: If the pressure of the gas spring is lowered, depending on the load, there is a risk of the axis falling when the servo is turned off in the maximum radius position.)

What to do under pressure

- Above 100 bar: No or little leakage. Maintain or charge to 140 bar.

- Below 100 bar:

- When gas charging is possible: If the pressure is maintained after charging, use it. If there is a rapid leak after charging, request gas spring replacement or repair. The lifespan of the gas spring is 3 to 4 years (20,000 hours), and periodic repair/replacement is recommended.

- If there is no charger: Contact Hyundai Robotics A/S. (Gas charging and exchange)

Apply monitoring software

- Provides a function to monitor the pressure of the gas spring for efficient management. (Applies to MV40.11 or higher, recommended MV40.17 or higher)